Kilnbuilding; Safety Controller Layout

Kilnbuilding; Safety Controller Layout

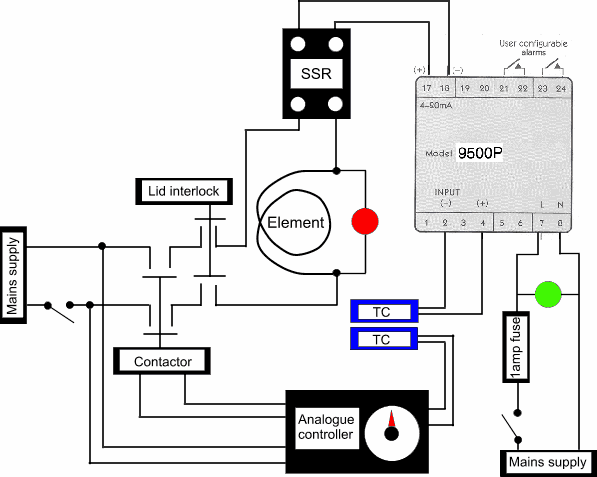

To reduce the possibility of a run-away kiln, this controller is designed with a separate safety circuit.

This is a schematic layout of the various components;

Kit list:

RS part numbers and descriptions;

223-972 £15.03 Enclosure, grey, metal, equipment housing, two tone, 203.2x177.8x88.1mm

380-6075 £12.23 Fan, AC, sleeve bearing, Sunon, 80x80x38

589-733 £2.02 Neon, indicator, round, prominent, tag 250mm connection, 220V, red

589-749 £2.20 Neon, indicator, round, prominent, tag 250mm connection, 220V, green

246-6531 £0.07 Connector, crimp terminal, 2.8x0.8 receptacle, 0.2-0.56mm

246-6604 £0.02 Connector, crimp terminal, 2.8mm, insulator boot

380-6075£12.23 Fan, AC, sleeve bearing, Sunon, 80x80x38mm, 230V

534-806£6.72 Crimp, tool, connector, dual purpose

>RS electronics website: http://rswww.com/

Description:

This is the thermocouple supplied by CAL controls. 6mm dia x 100mm long. The cable is stainless steel braided. It slides into a ceramic sheath (or bell-end tube), drilled into the side of the kiln. The ceramic sheath protudes into the kiln chamber by approximately 35mm.

This is the thermocouple supplied by CAL controls. 6mm dia x 100mm long. The cable is stainless steel braided. It slides into a ceramic sheath (or bell-end tube), drilled into the side of the kiln. The ceramic sheath protudes into the kiln chamber by approximately 35mm.

>CAL controls website; http://www.cal-controls.com

Two types of solid state relay (SSR) shown here; light and heavy duty. The heavy duty one on the left has a built-in heatsink. This is the type I use and it's mounted horizontally within the casing, so that there is maximum surface exposure for cooling purposes. The cooling fan is mounted directly underneath it.

Two types of solid state relay (SSR) shown here; light and heavy duty. The heavy duty one on the left has a built-in heatsink. This is the type I use and it's mounted horizontally within the casing, so that there is maximum surface exposure for cooling purposes. The cooling fan is mounted directly underneath it.

The SSR on the right needs to be fitted to a heatsink to dissipate the heat generated. Using silicon (supplied by CAL controls but also by RS electronics) to make a good conducting bond between the two and so prolong the life of the SSR.

As you can see from the schematic diagram at the top of the page, there is a red led lamp running in parallell with the element. So you can see when current is going to the element.

As you can see from the schematic diagram at the top of the page, there is a red led lamp running in parallell with the element. So you can see when current is going to the element.

Also on the CAL 9500P, you can see that the small green indicator light on the face of the controller comes on when the controller has has closed the SSR. But it doesn't show that current is going to the element. That's why I've fitted a lampe in the element circuit. Also so my eyes can see from across the other side of the studio without wearing glasses.

Also shown is the power switch for the controller itself.

So here you can see the target temperature is 570degC. The actual temp inside the kiln is 56degC. There are other neat tricks you can set up by means of the 'user configurable alarms' on the CAL9500P, apparently.

So here you can see the target temperature is 570degC. The actual temp inside the kiln is 56degC. There are other neat tricks you can set up by means of the 'user configurable alarms' on the CAL9500P, apparently.

Here the controller has put the power on again. The (red) element lamp is on and the element is live.

Here the controller has put the power on again. The (red) element lamp is on and the element is live.

This is the analogue box. This runs on a seperate circuit and is the failsafe. The fusing temperature I use is 800degC, so if I set the analogue controller to cut off at 840degC, that's what it will do; thus allowing me to leave the kiln for a day or two if necessary and not have to worry about the SSR failing in the closed position, resulting in a runaway. The kiln gets hotter and hotter and hotter until the elements melt. Then it can cool down.

This is the analogue box. This runs on a seperate circuit and is the failsafe. The fusing temperature I use is 800degC, so if I set the analogue controller to cut off at 840degC, that's what it will do; thus allowing me to leave the kiln for a day or two if necessary and not have to worry about the SSR failing in the closed position, resulting in a runaway. The kiln gets hotter and hotter and hotter until the elements melt. Then it can cool down.

If there is a power failure during the firing schedule, the contactor releases in the open position and the circuit cannot be made again until the soak/cut off switch is remade.

Power cable going in the left side, power to the element from underneath. The green lead goes to the (other) thermocouple.

Power cable going in the left side, power to the element from underneath. The green lead goes to the (other) thermocouple.

Disclaimer: This is the controller I designed and it works for me. You are free to copy any part of it on the understanding that if you blow yourself up or kill yourself or even worse (for whoever finds you and has to mop up the bits that is), fry yourself, it's entirely on your head. I'm not telling you what to do, just showing you what I do, simple as.

--Swampy 22:44, May 17, 2007 (EDT)